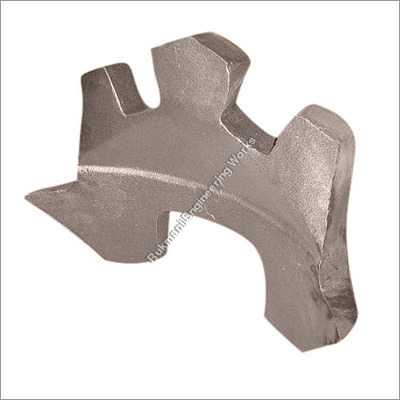

Hub Spacers Casting

Hub Spacers Casting Specification

- Surface Treatment

- Shot Blasted

- Process

- Sand Casting

- Product Type

- Automobile Hub Spacer

- Material

- Cast Iron

- Surface

- Smooth

- Dimension (L*W*H)

- Customized

- Size

- Standard/Custom

- Application

- Automotive, Machinery

- Color

- Metallic Grey

- Compatibility

- OEM and ODM available

- Production Capacity

- 10000 pcs/month

- Pack Type

- Wooden Crate/Carton Box

- Service Life

- Long

- Heat Resistance

- Up to 400°C

Hub Spacers Casting Trade Information

- Minimum Order Quantity

- 1 Ton

- FOB Port

- chennai

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 2 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Australia, Middle East, Africa, Western Europe, Central America, South America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008 & PED Certificate

About Hub Spacers Casting

We have established ourselves as a leading manufacturer, exporter and supplier of highly durable Hub Spacers Casting. Our diligent professionals make use of premium quality raw material and pioneering technology in the manufacturing process of the offered casting. The Hub Spacers Casting provided by us finds wide usage in general engineering and automobile industries. Besides, our honorable clients can get these castings in various dimensions and specifications according to their specific requirements at highly competitive prices.

Features:

-

Easy installation

-

Sturdy design

-

Dimensionally accurate

-

Rust resistance

Engineered for High Demands

Our Hub Spacers are designed for long service life and outstanding heat resistance. Thanks to precise sand casting and shot-blasting surface treatment, each spacer provides optimal performance in both automotive and heavy machinery settings. The smooth, metallic grey finish enhances their reliability and appearance.

Tailored Production & Secure Packaging

Choose from standard or fully customized dimensions to suit your requirements. With a production capacity of 10,000 pieces each month, we handle bulk orders with ease. Each product is carefully packed in wooden crates or carton boxes to guarantee safe delivery, wherever your business is located.

FAQs of Hub Spacers Casting:

Q: How are the Hub Spacers manufactured?

A: These hub spacers are produced via a sand casting process using premium cast iron. After casting, the surface undergoes shot blasting, ensuring smoothness and enhanced durability suitable for automotive and industrial machinery applications.Q: What benefits does the high heat resistance offer?

A: Withstanding temperatures up to 400C, these spacers can be used in machinery and automotive parts exposed to intense heat, ensuring long operational life and consistent performance even in challenging environments.Q: When should I consider using customized dimensions?

A: Customized hub spacers are ideal when your application requires specific fitting or unique specifications that standard sizes cannot provide. We support bespoke designs to ensure compatibility with your machinery or vehicle needs.Q: Where can the Hub Spacers be applied?

A: They are suitable for a variety of automotive and machinery applications, including wheel hubs, drive shafts, and other rotary components requiring precise spacing and alignment under high-stress conditions.Q: What is the packaging method for shipping the spacers?

A: Each order is securely packed in either sturdy wooden crates or carton boxes. This ensures that all spacers arrive safe and undamaged, whether shipped locally within India or exported internationally.Q: How does the smooth surface treatment enhance product quality?

A: A shot-blasted, smooth surface reduces friction, minimizes wear, and prevents early corrosion. This translates to improved longevity and operational efficiency in high-demand environments.Q: What are the advantages of working with an OEM or ODM-compatible supplier?

A: Opting for OEM or ODM ensures that your unique specifications can be met, whether you require standard components or tailor-made spacers, thus supporting brand-specific solutions and a seamless supply chain.

- Minimum Order Quantity

- 1 Ton

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, Middle East, Africa, Western Europe, Central America, South America, Asia, Eastern Europe, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automotive Castings Category

Axle Top Pads Casting

Surface Treatment : Other, Shot Blasted or As Cast

Material : Other, High Tensile Cast Iron

Dimension (L*W*H) : Customizable as per requirement

Product Type : Other, Axle Top Pads Casting

Application : Used in Heavy Duty Vehicles and Trailers

Process : Sand Casting

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free