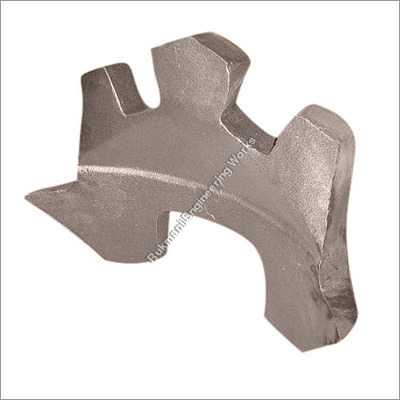

Axle Top Pads Casting

Axle Top Pads Casting Specification

- Surface Treatment

- Shot Blasted or As Cast

- Process

- Sand Casting

- Product Type

- Axle Top Pads Casting

- Material

- High Tensile Cast Iron

- Surface

- Smooth Finish

- Dimension (L*W*H)

- Customizable as per requirement

- Size

- Standard and Customized Sizes Available

- Application

- Used in Heavy Duty Vehicles and Trailers

- Casting Standard

- IS 210 / ASTM A48

- Minimum Order Quantity

- 100 Pieces

- Load Bearing Capacity

- Up to 20 Tons

- Tolerance

- ±0.5 mm

- Machinability

- Good

- Packaging

- Wooden Pallet or as required

Axle Top Pads Casting Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque

- Delivery Time

- 2 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Eastern Europe, Middle East, Western Europe, Central America, Australia, South America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008 & PED Certificate

About Axle Top Pads Casting

We are one of the notable manufacturers, exporters and suppliers of a premium quality Axle Top Pads Casting that is primarily used for engineering purposes. Designed by our experienced professionals, the casting provided by us is precisely manufactured by making use of optimum quality raw material and advanced machines. This casting is made available in various dimensions and finishes for our clients to choose from. The Axle Top Pads Casting provided by us is highly demanded for its qualitative attributes given below.

Features:

-

Sturdiness

-

Dimensional accuracy

-

Excellent finish

-

Corrosion resistance

High-Performance Casting for Heavy-Duty Demands

Our axle top pad castings are designed to excel in the most rigorous environments, supporting loads up to 20 tons. Utilizing premium high tensile cast iron, and precise sand casting methods, we deliver components that combine durability with a consistent, smooth finish. Each pad meets stringent industry standards to ensure dependable performance in heavy-duty vehicles and trailers.

Customizable Solutions for Diverse Applications

With both standard and tailored dimension options available, we cater to unique client requirements with flexibility. Whether you need specific lengths, widths, or heights, our manufacturing capabilities guarantee the right fit for your project. Expert surface treatments, adaptable packaging options, and compliance with global standards ensure satisfaction at every stage.

FAQs of Axle Top Pads Casting:

Q: How are Axle Top Pads Casting manufactured to ensure dimensional precision?

A: Each axle top pad is produced using the sand casting process, rigorously adhering to tolerance limits of 0.5 mm. The process is guided by IS 210 and ASTM A48 standards, ensuring consistent size and quality across batches.Q: What materials are used to manufacture these axle top pads, and what are their benefits?

A: Our axle top pads are made from high tensile cast iron, known for its exceptional strength, durability, and resistance to wear. This material secures optimal performance under heavy load conditions in commercial vehicles and trailers.Q: When should I consider using customized axle top pads instead of standard sizes?

A: Custom-sized axle top pads are recommended when your project requirements exceed or differ from industry standard sizes. We accommodate unique specifications for dimension, load capacity, and surface treatment to ensure seamless integration into your application.Q: Where are these axle top pads commonly used?

A: These casting pads are primarily utilized in heavy-duty vehicles and trailers, where robust load-bearing capacity and reliable dimensional stability are essential for safe and efficient operation.Q: What is the minimum order quantity for these axle top pads and how are they packaged?

A: The minimum order quantity is 100 pieces. Products are securely packed in wooden pallets or according to customer instructions to protect them during shipping and handling.Q: How does the surface treatment enhance the performance of axle top pads?

A: Surface treatments such as shot blasting or leaving the pads as cast provide a smooth, clean finish that aids installation, minimises wear, and reduces the likelihood of corrosion, thus enhancing the components operational lifespan.Q: What advantages does the sand casting process offer for axle top pad manufacturing?

A: Sand casting allows for the creation of both standard and custom designs with high dimensional accuracy and fine surface finish. This cost-effective process supports flexibility and scalability, making it ideal for small and large order volumes.

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Eastern Europe, Middle East, Western Europe, Central America, Australia, South America, Asia, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automotive Castings Category

Hub Spacers Casting

Minimum Order Quantity : 1 Ton

Surface : Smooth

Material : Other, Cast Iron

Color : Metallic Grey

Surface Treatment : Other, Shot Blasted

Size : Standard/Custom

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free