Ball Type Check Valves

Ball Type Check Valves Specification

- Features

- Good Quality

- Material

- MS

- Structure

- Control

- Usage

- Industrial

- Size

- Standard Sizes

- Media

- Water

Ball Type Check Valves Trade Information

- Minimum Order Quantity

- 1 Ton

- FOB Port

- chennai

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Ball Type Check Valves

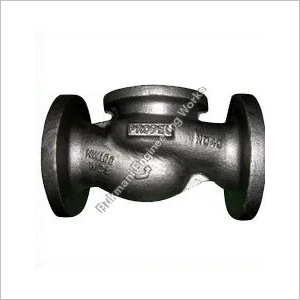

Ball Type Check Valves Castings (NRV) - Flanged (High Pressure model: R-01)

RUMAX Ball Type Check Valve (NRV) involves a very simple but robust design with no critical mechanism involved. Parts like Hinge, Pin, Disc etc., used in conventional Non Return Valve (NRV) are eliminated. This Ball Type Check Valve (NRV) works excellently in muddy / clear water, viscous liquid, paper stock, slurries, erosive and corrosive fluids.

|

|

* Innovative * Maintenance Free * Totally Leak Proof

|

|

|

|

Ball Type Check Valve (NRV) - Flanged (High Pressure model: R-01)

PRINCIPLE OF RUMAX BALL TYPE CHECK VALVE (NRV)

RUMAX Ball Type Check Valve (NRV) has involved in a reinforced rubber coated ball to arrest flow media in return condition. This ball moves totally out of the flow path when the pumping is on, to give minimum head losses (see Figure). The spherical rubber coated ball seals perfectly on the rounded valve seat ensuring a totally leak proof sealing.

EXCELLENT ADVANTAGES OF RUMAX BALL TYPE CHECK VALVE (NRV)

* Lower power consumption * Larger solid handling capacity * Self cleaning, Non-Clogging

* Perfect Sealing * Low pressure drop * Maintenance free, replacement of ball is very easy

* Works excellently in muddy / clear water, viscous liquid, paper stock, slurries

COMPARISION

|

RUMAX Ball Type Check Valve (NRV) |

CONVENTIONAL NRV |

|

Very low pressure drop across the valve which saves energy, reduces pump cycle time duration |

Comparatively high pressure losses, requires more energy increases pump cycle time duration. |

|

The sealing face is deposit free, since it remains inclined in any position of the valve, ensuring perfect sealing. |

Deposits on the sealing due to its flatness may not ensure perfect sealing. |

|

Clear passage, equal to nominal valve dia. gives larger solid handling capacity |

The Disc interference leaves less clear passage than the normal valve dia., hence smaller solid handling capacity |

|

Abrasion resistance of rubber ensures longer life. Also the cleanout port does not necessitate valve removal from the pipeline. Hence much shorter downtime. |

Parts may wear out due to abrasion. Also, valve may be removed from the pipeline for maintenance/ cleaning. Hence longer down time. |

- Works vertically or horizontally

- Dimensionally compatible with IS 5312 (F/F)

- Pressure Rating = PN 16

- Body test: 1.5 times rated Pressure

- Seat test: 1.1 times rated Pressure

- Dimensions (Valve size in mm)

|

Size(A) |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

|

D |

150 |

165 |

185 |

200 |

220 |

250 |

285 |

340 |

395 |

|

L |

174 |

200 |

240 |

260 |

300 |

350 |

400 |

500 |

600 |

|

H |

160 |

180 |

210 |

230 |

280 |

340 |

400 |

500 |

570 |

|

T |

15 |

16 |

16 |

19 |

20 |

21 |

21 |

22 |

24 |

Part List / Material of Construction

|

Part |

Description |

Material |

|

1. |

Body |

* Cast Iron |

|

2. |

Cover |

* Cast Iron |

|

3. |

Ball |

Nitrile Rubber |

|

4. |

Cover Ring |

Nitrile Rubber |

|

5. |

Ball Seat Ring |

L.T. Bronze |

|

6. |

Fasteners |

Carbon Steel |

* WCB & SS on request

Reliable Flow Control Solution

Our Ball Type Check Valves are crafted for dependable performance in controlling water flow within industrial processes. Their quality MS construction ensures durability and strength, making them a preferred choice where long-term service and resistance to wear are crucial. Designed for seamless integration into existing systems, these valves safeguard against leakage and reverse flow.

Advanced Manufacturing Standards

Each valve is manufactured with precision under strict quality controls. Utilizing premium raw materials and advanced fabrication techniques, our valves offer consistent performance and longevity. As a leading exporter and supplier in India, we prioritize safety, efficiency, and customer satisfaction with every unit delivered.

FAQs of Ball Type Check Valves:

Q: How do ball type check valves function in industrial water systems?

A: Ball type check valves utilize a spherical ball to permit flow in one direction while automatically blocking reverse flow, ensuring water only moves as intended within industrial pipelines.Q: What are the benefits of using MS (Mild Steel) material in these check valves?

A: Mild Steel provides excellent strength and durability, making these valves resilient to pressure and wear, while also offering cost-effectiveness for industrial applications.Q: When should I consider installing a ball type check valve in my system?

A: Ball type check valves should be installed whenever you need to prevent backflow and maintain unidirectional water flow in industrial settings or whenever system reliability is paramount.Q: Where can these valves be used effectively?

A: These check valves are ideally suited for water handling in industrial environments such as water treatment plants, process industries, and other facilities requiring reliable flow control.Q: What is the manufacturing process for these check valves?

A: The valves are fabricated using high-quality MS, shaped and machined to precision, assembled with robust internal components, and subjected to rigorous quality testing to ensure performance.Q: How does the quality of these valves ensure operational efficiency?

A: With their robust structure and meticulous quality checks, these valves minimize maintenance needs and reduce downtime, resulting in efficient and uninterrupted industrial operations.

- Minimum Order Quantity

- 1 Ton

- Delivery Time

- 4 Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valves Category

Stainless Steel Foot Valve

Minimum Order Quantity : 1 Ton

Structure : Other, Spring Loaded Check Valve

Material : Stainless Steel 304/316

Media : Other, Water, Oil, Noncorrosive Liquids

Power : Manual

Application : Water Supply, Irrigation, Industrial Pipelines

Swing Check Valve castings

Minimum Order Quantity : 1 Ton

Structure : Other, Single Disc, Swing Type

Material : Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel, Alloy Steel

Media : Other, Water, Gas, Oil, Steam

Power : Manual

Application : Industrial, Water, Oil, Gas

Globe Valve Castings

Minimum Order Quantity : 1 Ton

Structure : Other, Bolted bonnet, streamlined body design

Material : Cast iron, carbon steel, stainless steel, alloy steel

Media : Other, Water, steam, oil, gas

Power : Manual

Application : Industrial pipelines, water, steam, and oil control

Gate Valve Castings

Minimum Order Quantity : 1 Ton

Structure : Other, Solid wedge, bolted bonnet

Material : Cast iron, ductile iron, carbon steel, stainless steel, alloy steel

Media : Other, Water, steam, oil, gas, chemicals

Power : Other, Manual, Electric, Pneumatic

Application : Industrial piping, oil & gas, petrochemical, waterworks, and power plants

Send Inquiry

Send Inquiry Send SMS

Send SMS